PATRIK BOARDS - BOUTIQUE BRANDS

PATRIK BOARDS – BOUTIQUE BRANDS

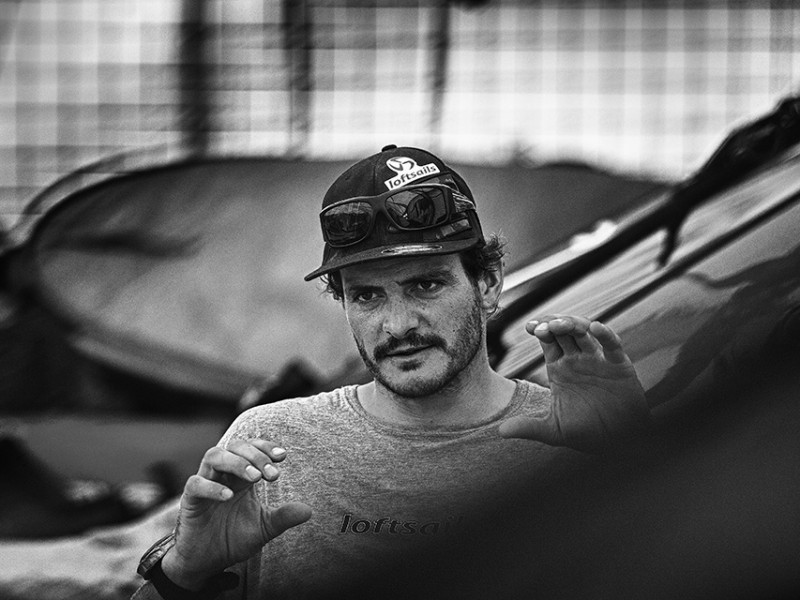

Pro windsurfing couple Patrik Diethelm and multiple World Champion Karin Jaggi eat, sleep and breathe windsurfing together. Their PATRIK brand name is the result of countless hours of refining their no BS, sailor-oriented shapes. Karin tells us all about their brand values and unique selling points.

(This feature originally appeared in the July 2014 issue of Windsurf Magazine. To read more features like this first, Print and Digital subscriptions are available. Prices include delivery globally for 10 x issues a year!)

What is your brand philosophy and the reason you both started Patrik after years with F2?

Patrik and I were with F2 for decades – first as normal end consumers, then team riders and finally working for the company for many years. When F2 got sold out of the B&M group we decided to stay but unfortunately it didn’t work out with the new owners. To be able to start our own brand was a dream come true. Finally we could really follow up our own ideas and create our own brand philosophy. We do quite a few things different than all other brands. For example we don’t have a yearly range, but simply a current one. Also, we don’t offer boards in several constructions because we are convinced that there’s only one perfect construction for a type of board. Ourselves and our partners agree that discounting is the wrong way to go. So we fix our prices at a realistic level instead of advertising them really high and then simply giving loads of markdown back to the ‘real’ level again. Basically, we just try to be really honest and open about what we do.

What is your production cycle? Annual releases, two-yearly?

We don’t have a yearly cycle but simply a current range. We test new shapes and ideas all year round but will only put a board into production when it’s really better than the current model. This gives us the advantage to react quickly to a new idea or also to stay with some proven designs. For me, personally – as a professional windsurfer – this is a massive advantage as it gives me the time to really get to know a board and therefore also be able to get the best performance from it. Because we don’t change models and graphics yearly we also have a high re-sale value.

What are the key highlights/benefits of your construction layup?

When it comes to construction I believe there are 2 key elements: maximum best performance and long lasting durability. To reach those goals we firstly use only materials we believe are the best, regardless of the production costs. But it’s not always the most expensive material that proves to be the best for every board. This is where Patrik [Diethelm] really has a lot of knowledge and understanding. Carbon is great and expensive but cracks very easily. Kevlar on the other hand is tough but not so stiff, etc. We do extensive testing with materials and then decide on what we think works best for a board. Once you have the right material it’s important how you construct the board. Which layer goes where to again keep maximum performance and light weight – but make the board strong enough for its purpose? For example to just add a few extra layers does not need to make the board any stronger. After 5 years on the market we get great feedback that customers have realised how strong our boards are.

Where is your production based?

We produce at Cobra in Thailand – like most other brands. Our advantage is that Patrik spends a lot of time there and therefore can not only understand how the production works but also keep an eye on it and react quickly if it’s necessary. To understand how a production run really works and what their limit is, is absolutely crucial for us. When shaping a board Patrik always considers if it will be easy to produce it in the factory. E.g., it’s easy for the production team to measure a straight but very hard or actually impossible to reproduce a perfect concave. That’s why Patrik came up with the ‘inverted V’ instead of a concave. The result is really accurate boards with very little production tolerances. This is important for the end consumer, who doesn’t get to choose one board from a selection of ‘identical’ ones like a pro.

What is the most important thing a good mass-production factory needs to keep your business?

Quality and reliability. For sure by the end the price is a factor as well but without good quality of production and the security that products will be available even the best price won’t have any importance. This is why Cobra pretty much has a monopoly.

Signing Ricardo Campello is a big statement. Is it in your philosophy to stay low profile or to have the big names using your gear?

Definitely not low profile – I would rather say small and exclusive. We didn’t plan at all to sign Ricardo – or any other ‘big’ name. It just happened! We are very happy though to have him on PATRIK and think he’s a perfect match for us: very passionate, a bit crazy, ready to take a lot of risks and always going ‘big’. He represents our brand very well.

What’s Ricardo’s feedback been like so far?

Patrik has spent 2 weeks on Maui with him and is constantly in contact ever since. Now he has just shaped 12 new boards for Ricardo – so it will be a while till we get all feedback together. But it seems to be a very constructive and well working relationship.

Thanks for your input!

The post PATRIK BOARDS – BOUTIQUE BRANDS appeared first on Windsurf Magazine.